|

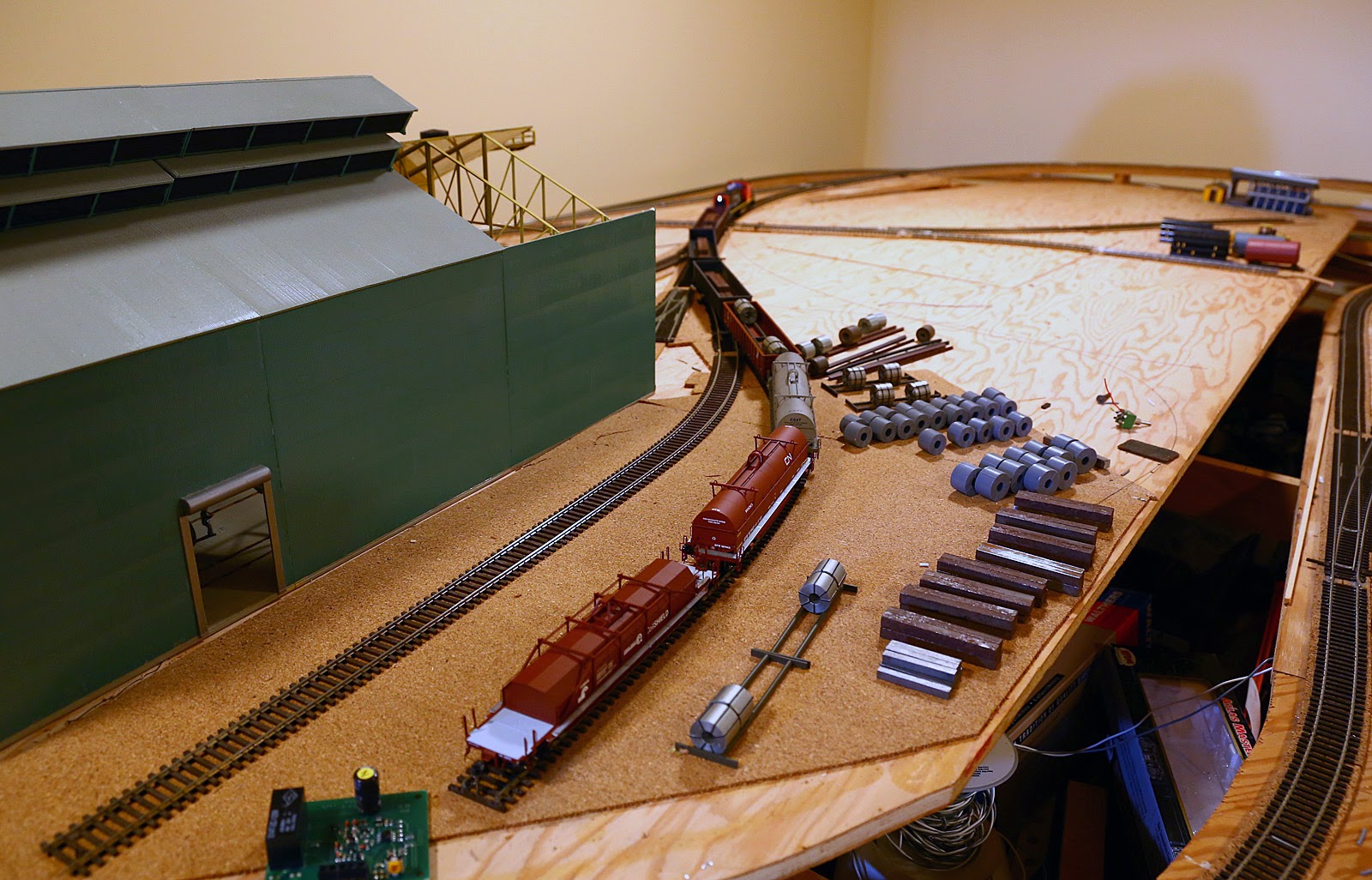

| CN 1906 pulls the first loads out of the recently-installed storage tracks in front of the Stelco (Walthers) rolling mill. Looks like they will soon have plenty more loads to pull! |

A few days spent working on the layout over the Christmas break yielded

some significant progress on the layout, namely completing the trackage on the

spur on the left (east) side of the layout. More industries to go and switch

now!

Carpentry

The basic benchwork was already in place, including a sheet of plywood cut

to fit in the available space; all that remained was to secure the sub-roadbed

in place. It was decided to use the two “high-line” switches already in place

to access the spur rather than run a new branch off of the existing yard lead. This

meant that the spur would be at a higher elevation than previously planned –

this allows a more eye-level view of activity on the spur, rather than a more

eye-in-the-sky view. This also helps to blend the high line into the rest of

the layout, rather than it creating a “stair case” illusion and seem to

arbitrarily rise out of the rest of the layout. A total of seven supports were

cut from spare 1x3” stock to elevate the plywood about four inches. Since the

two high line switches were at slightly different elevations due to the grade

that they are on, the elevation of the plywood sheet was set to split the

difference between the two. Three supports were fastened to the benchwork lengthwise

along the plywood and four were installed transversely – this stabilized the

plywood and makes it resistant to any bumps or jolts on the rest of the layout’s

benchwork. As this particular piece of plywood had been stored for a number of

years, one end of the sheet (south end) had developed a significant warp (curl)

that required a 2x4” attached transversely to the bottom to help straighten it

out (2x4 was planed to be perfectly straight). The last step in preparing the

plywood was to cut a hatch approximately 16” square into the middle; this not

only allows access in the event of a derailment or electrical glitch, but will

help with scenic-ing the layout as well. The seven risers (supports) were first

screwed to the bottom of the plywood at pre-marked and measured locations. Once

all were in place, the plywood was positioned at the appropriate height and the

risers clamped in place while pilot holes were drilled and screws put in place.

The sub-roadbed between the two switches on the high line consists of a segment

of plywood approximately six inches wide; a tapered “bridge” piece was placed

between this existing sub-roadbed and the newly installed plywood.

Surprisingly, very little adjustment was needed to align the three pieces of

plywood, and only some slight planing and sanding was required to smooth the

transition from the high line grade to the level plywood surface.

Once the plywood was installed, it was full speed ahead with the

trackwork for the new spur (actually two spurs that cross at a diamond, but

referred to as the spur for clarity). The facing high line switches each feed

one of two tracks that meet at a 90° crossing. The track on the spur is mostly code

83, a mix of Atlas, Shiniohara, and Peco. The north end of the

spur consists of a Walthers rolling mill (to be featured in a later post) that

was cut back to three segments (from original four) and another track next to the rolling mill that will

serve as a bulk fuel dealer. Two tracks will go into the mill building itself, and another two storage tracks were laid next to the building to hold the loads for pickup. The rails have not yet been installed in the building, as the channels in the floor are intended for a cars' wheel flanges, not actual rails. Hence the gap is too narrow to lay rail (gauge is too tight), but that will soon be corrected. These tracks cross over the

access hatch on three sides – each crossing was secured with extra spikes to ensure

the alignment remains intact.

To power the new spur, a new track bus was run under the

previously-unpowered high line and feeders installed between the rails and the

bus wires. Since the high line circles around and forms a reversing loop with what

is essentially the tail of the south yard lead (better-sounding name TBD), a

Digitrax auto-reverser was purchased. Mark made quick work wiring up, so now we

can run trains in a continuous loop up and around the high line.

|

| After lifting cars from Stelco, two empty cars are lifted from the bulk fuel dealer. Extra track is stored temporarily at left. Note the high-tech temporary end of track device! |

Operations

Prior to completing the spur, there were only two industries already in

place on the layout, the grain elevator and the spur near the bridge (at least

for now, “Casco”). The addition of four new industries to switch will now

provide at least enough work for two jobs: a yard job to handle the sorting of

the cars and blocking of mainline freights, as well as switch the grain

elevator and Casco, and a second job to go and switch the spur. With increased

traffic on the layout, this will soon provide the opportunity to implement and

learn about track clearances, car card systems, and how to develop a natural “flow”

to operations between multiple operators. Can’t wait!

|

| Lifting cars from the Stelco storage tracks at right; soon more empties will be spotted inside the building. |

Stay tuned for part II of the layout update sometime later in the week…

Thanks for looking,

Cheers,

Peter.

No comments:

Post a Comment